সিএনসি মেশিন টুলস পজিশনিং সঠিকতা সনাক্ত করার 7 উপায়

The positioning accuracy of CNC machine tools refers to the positional accuracy that can be achieved by the movement of each coordinate axis of the machine tool under the control of the numerical control device. The positioning accuracy of CNC machine tools can be understood as the motion accuracy of the machine tool. Ordinary machine tools are manually fed. The positioning accuracy is mainly determined by the reading error. The movement of the CNC machine tool is realized by digital program instructions, so the positioning accuracy is determined by the numerical control system and mechanical transmission error.

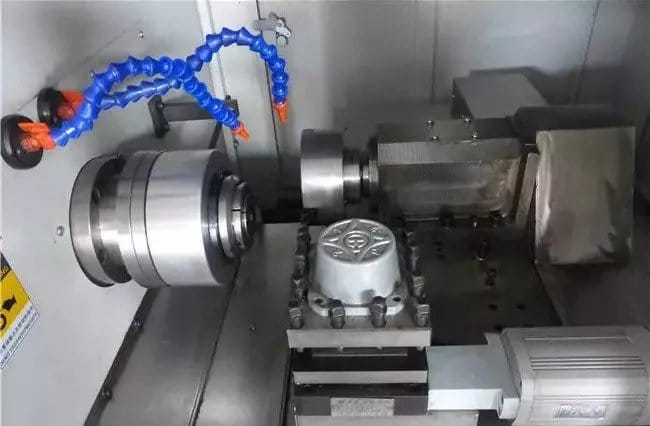

CNC machine tool is the abbreviation of digital control machine tool, which is an automatic machine tool with a program control system. The control system is capable of logically processing a program having control code or other symbolic instructions and decoding it, using coded digital representations, and Nanjing Fourth Machine Tool Co., Ltd. inputs the numerical control device through the information carrier. Through the arithmetic processing, various control signals are issued by the differential control device to control the movement of the machine tool, and the parts are automatically processed according to the shape and size required by the drawings.

The movement of each moving part of the machine tool is completed under the control of the numerical control device. The precision that each moving part can achieve under the control of the program command directly reflects the precision that the machined part can make. Therefore, the positioning accuracy is an important test. Content.

1. Linear motion positioning accuracy detection

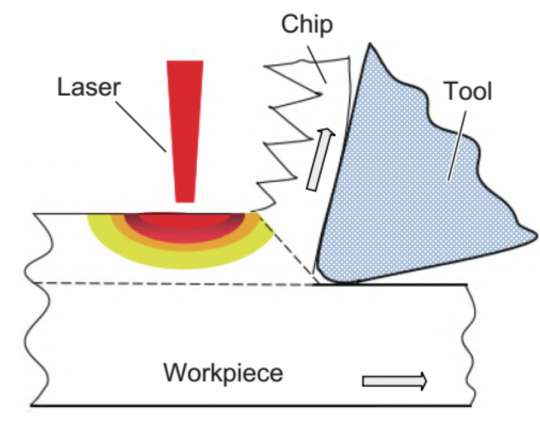

Linear motion positioning accuracy is generally performed under no-load conditions on machine tools and benches. According to the national standards and the provisions of the International Organization for Standardization (ISO standards), the detection of CNC machine tools should be based on laser measurements. In the absence of a laser interferometer, it is also possible for the average user to use a standard scale with an optical reading microscope for comparative measurements. However, the accuracy of the measuring instrument must be one to two levels higher than the accuracy of the measurement.

To reflect all the errors in multiple positioning, the ISO standard stipulates that each positioning point calculates the average value and the dispersion difference based on five measurement data, and the dispersion difference band formed by the dispersion band.

2, linear motion repeat positioning accuracy detection

The instrument used for the test is the same as that used to detect thepositioning accuracy. The general detection method is to measure at any three positions near the midpoint and the two ends of each coordinate stroke. Each position is quickly moved, and the positioning is repeated 7 times under the same conditions. The stop position value is measured, and the maximum reading difference is obtained. Taking one-half of the most significant difference among the three positions, the positive and negative signs are attached as the repeated positioning accuracy of the coordinates, which is the most basic index reflecting the stability of the axis motion accuracy.

3, linear motion origin return accuracy detection

The origin return precision is essentially the repeat positioning accuracy of a special point on the coordinate axis, so its detection method is completely the same as the repeat positioning accuracy.

4. Reverse error detection of linear motion

The opposite error of the linear motion also called the loss amount, includes the reverse dead zone of the drive position (such as servo motor, servo motor, and stepping motor) on the coordinate axis feed chain, and each mechanical motion transmission pair A comprehensive reflection of errors such as backlash and elastic deformation. The larger the error, the lower the positioning accuracy and the repeat positioning accuracy.

The detection method of the reverse error is to move a distance forward or backward in the stroke of the measured coordinate axis and use the stop position as a reference, and then give a specific movement command value in the same direction to make it move a distance. Then run the same distance in the opposite direction and measure the difference between the stop position and the reference position. The measurement has performed a plurality of times (generally seven times) at three points near the midpoint and both ends of the stroke, and the average value at each position is obtained, and the maximum value among the obtained average values is the reverse error value.

5. Positioning accuracy detection of rotary table

Measuring tools include standard turret, angle polyhedron, circular grating and collimator (collimator), etc., which can be selected according to the specific conditions. The measurement method is to make the table forward (or reverse) to an angle and stop, lock, and position. Use this position as a reference, then quickly turn the table in the same direction and measure every 30 locks. Each of the forward rotation and the reverse rotation is measured for one week, and the maximum value of the difference between the actual rotation angle of each positioning position and the theoretical value (command value) is the division error.If it is a CNC rotary table, it should be a target position every 30, for each target position to quickly locate 7 times from the positive and negative directions, the difference between the area and the target position is actually reached, and then according to GB10931- 89 The method specified in the “Method for Evaluating the Position Accuracy of Digital Control Machines” calculates the average position deviation and standard deviation, the difference between the maximum value of all the average position deviations and the standard deviation and the sum of all the average position deviations and the standard deviation. It is the positioning accuracy error of the CNC rotary table.

Considering the dry-type transformer to the actual use requirements, it is generally essential to measure several equal-angle points such as 0, 90, 180, 270, etc., and the accuracy of these points is required to be improved by one level compared with other angular positions.

6. Repeated indexing accuracy detection of rotarytable

The measurement method is repeated three times in three places in one week of the rotary table, and the detection is performed in the forward and reverses directions respectively. The maximum value of the difference between the values of all readings and the theoretical value of the corresponding position. If it is a CNC rotary table, take one measurement point every 30 as the target position, and perform five fast positionings for each target position from the positive and negative directions respectively, and measure the difference between the actual arrival position and the target position. That is, the position deviation, and then calculate the standard deviation according to the method specified in GB10931-89, which is six times of the maximum value of the standard deviation of each measuring point, which is the repeating indexing precision of the numerical control rotary table.

7. The origin return accuracy detection of the rotary table

The measurement method is to perform the origin return from 7 arbitrary positions, measure the stop position, and use the maximum difference read as the origin return accuracy.

It should be pointed out that the detection of the current positioning accuracy is measured under the condition of fast and positioning. For some CNC machine tools whose feeding system is not very good, different positioning accuracy values will be obtained when positioning with varying speeds of feed. Also, the measurement result of the positioning accuracy is related to the ambient temperature and the working state of the coordinate axis. At present, most of the numerical control machine tools adopt a semi-closed loop system, and the position detecting components are mostly mounted on the driving motor, which generates an error of 0.01 to 0.02 mm in a stroke of 1 m. It is not strange. This is an error caused by thermal elongation, and some machines use a pre-stretch (pre-tightening) method to reduce the impact.

The repeating positioning accuracy of each coordinate axis reflects the most basic accuracy index of the shaft, which reflects the stability of the motion accuracy of the axle, and it cannot be assumed that the machine tool with poor precision can be stably used for production. At present, due to the increasing number of functions of the numerical control system, system errors such as pitch accumulation error and backlash error can be compensated for the motion accuracy of each sitting injector. Only the random error cannot be paid, and the repeat positioning accuracy is repeated. It reflects the absolute random error of the feed drive mechanism. It can’t be corrected by the CNC system compensation. When it is found to be out of tolerance, only the fine adjustment of the feed drive chain is performed. Therefore, if the machine tool is allowed to be selected, it is better to choose a machine with high repeatability.