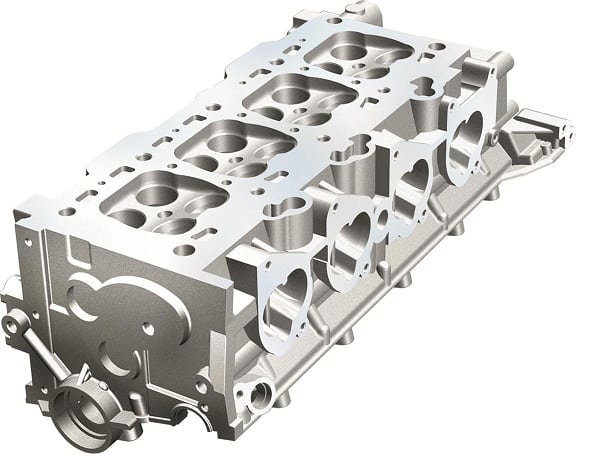

La culata es uno de los componentes clave de un motor, con una superficie de montaje de cova como la superficie superior, la superficie inferior se acopla con la superficie superior en el cuerpo del cilindro, la superficie de la junta del tubo de escape en dos lados, la cubierta frontal en la parte delantera, la transmisión en la parte delantera. trasero, respectivamente. Las seis superficies son superficies de acoplamiento, que requieren una dimensión precisa, perpendicularidad entre sí, buena planitud y menor rugosidad de la superficie.

La culata es uno de los componentes clave de un motor, con una superficie de montaje de cova como la superficie superior, la superficie inferior se acopla con la superficie superior en el cuerpo del cilindro, la superficie de la junta del tubo de escape en dos lados, la cubierta frontal en la parte delantera, la transmisión en la parte delantera. trasero, respectivamente. Las seis superficies son superficies de acoplamiento, que requieren una dimensión precisa, perpendicularidad entre sí, buena planitud y menor rugosidad de la superficie.

The rapid development of cutting technology brings about high-speed and high efficiency. In order to achieve high-efficiency and high-speed machining of cylinder head, it requires scientific, advanced and reasonable processing technology and high-performance machines, as well as professional cutting tools.

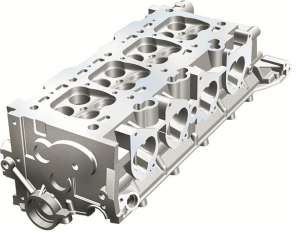

Cylinder face milling and boss machining

AMA01、AMP01 series high-speed milling cutter. Cutter body is made of high-strength aluminum with special treatment, with light weight, cutting speed up to 5000m/min, good dynamic balance performance and high-precision

Multi-functional milling

AL series endmills, with shape cutting edge and large helical angle design, can effectively prevent built-ups from occurring. Impact-resistance design on whole edges can achieve high surface quality.

Semicircle hole-making

BMR04 series  ball-nose endmills for finishing, with excellent cutting performance and high feed rate for profiling, is suitable for semi-finishing and finishing.

ball-nose endmills for finishing, with excellent cutting performance and high feed rate for profiling, is suitable for semi-finishing and finishing.

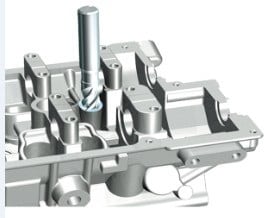

Stepped hole machining

Special tools, with stepped edges, screw clamping, easy insert indexing, only one tool can finish all the profile with high efficiency.

Sparking plug machining

Drilling: the dedicated drills for sparking plug, only one pass for hole-making and chamfering with high-efficiency.

Tapping: optimized design of brand-new taps, can achieve high precision thread machining.

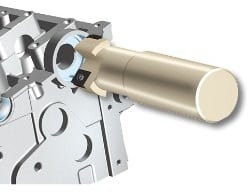

Conduct hole making

Solution 1:

Drilling before reaming

Drilling: with excellent self-centering capability, straight drill is capable of machining aluminum material, can achieve relatively high positioning, straightness and surface finish.

Reaming: is dedicated reamer for guide hole-making, with double chip pockets design, smooth chip removal, internal-coolant supplying with sufficient cooling, can achieve high cylindricity, concentricity with high precision.

Solution 2:

Tailor-made and non-standard cutting tools, with guide hole and seat ring completed in one operation, can achieve high positioning consistency and save passes.

Cavity machining

Side and face milling cutter,screw clamping system ensures high precision and excellent surface quality, double teeth structure design guarantee high efficiency.