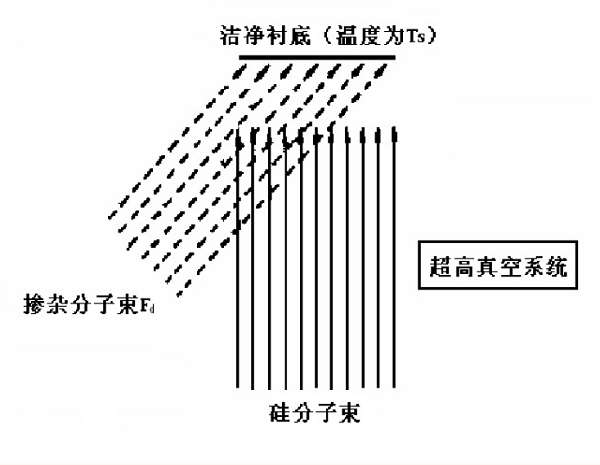

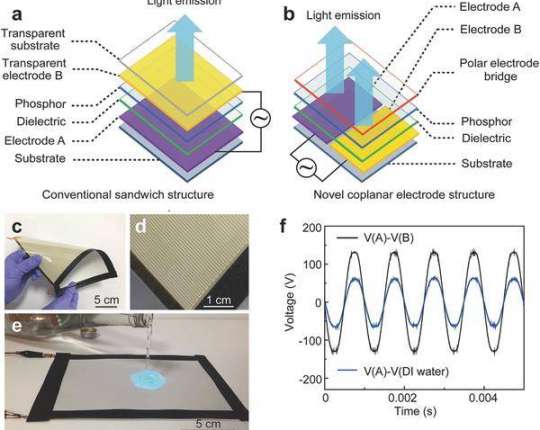

First, the molecular beam epitaxial profileIn the ultra-high vacuum environment, with a certain thermal energy of one or more molecules (atoms) beam jet to the crystal substrate, the substrate surface reaction processMolecules in the “flight” process almost no collision with the ambient gas, in the form of molecular beam to the substrate, the epitaxial growth, hence the name.Properties: A vacuum deposition methodOrigin: 20th century, the early 70s, the United States Bell laboratoryApplications: epitaxial growth atomic level precise control of ultra-thin multi-layer two-dimensional structure materials and devices (super-character, quantum wells, modulation doping heterojunction, quantum yin: lasers, high electron mobility transistors, etc.); combined with other processes, But also the preparation of one-dimensional and zero-dimensional nano-materials (quantum lines, quantum dots, etc.).Typical features of MBE:(1) The molecules (atoms) emitted from the source furnace reach the substrate surface in the form of a “molecular beam” stream. Through the quartz crystal film thickness monitoring, can strictly control the growth rate.(2) molecular beam epitaxy growth rate is slow, about 0.01-1nm / s. Can achieve single atomic (molecular) layer epitaxy, with excellent film thickness controllability.(3) By adjusting the opening and closing of the baffle between the source and the substrate, the composition and the impurity concentration of the film can be strictly controlled, and selective epitaxial growth can be achieved.(4) non-thermal equilibrium growth, the substrate temperature can be lower than the equilibrium temperature, to achieve low temperature growth, can effectively reduce the interdiffusion and self-doping.(5) with reflective high-energy electron diffraction (RHEED) and other devices, can achieve the original price observation, real-time monitoring.Growth rate is relatively slow, both MBE is an advantage, but also its lack, not suitable for thick film growth and mass production.Second, silicon molecular beam epitaxy1 basic profileSilicon molecular beam epitaxy includes homogeneous epitaxy, heteroepitaxy.The silicon molecular beam epitaxy is the epitaxial growth of silicon (or silicon-related materials) on a suitably heated silicon substrate by physical deposition of atoms, molecules or ions.(1) during the epitaxial period, the substrate is at a lower temperature.(2) Simultaneous doping.(3) the system to maintain high vacuum.(4) pay special attention to the atomic clean surface.Figure 1 Schematic diagram of the working principle of silicon MBE2 Development history of silicon molecular beam epitaxyDeveloped relative to CVD defects.CVD defects: substrate high temperature, 1050oC, to the doping serious (with high temperature). The original molecular beam epitaxy: the silicon substrate heated to the appropriate temperature, vacuum evaporation of silicon to the silicon substrate, the epitaxial growth.Growth Criteria: The incident molecules move sufficiently to the hot surface of the substrate and are arranged in the form of a single crystal.3 The importance of silicon molecular beam epitaxyThe silicon MBE is carried out in a strictly controlled cryogenic system.(1) can well control the impurity concentration to reach the atomic level. The undoped concentration is controlled at <3 × 1013 / cm3.(2) The epitaxy can be carried out under the best conditions without defects.(3) The thickness of the epitaxial layer can be controlled within the thickness of the single atomic layer, superlattice epitaxy, several nm ~ several tens of nm, which can be designed manually, and the preparation of excellent performance of the new functional materials.(4) Homogeneous epitaxy of silicon, heteroepitaxy of silicon.4 epitaxial growth equipmentDevelopment direction: reliability, high performance and versatilityDisadvantages: high prices, complex, high operating costs.Scope: can be used for silicon MBE, compound MBE, III-V MBE, metal semiconductor MBE is developing.Basic common features:(1) basic ultra-high vacuum system, epitaxial chamber, Nuosen heating room;(2) analysis means, LEED, SIMS, Yang EED, etc .;(3) injection chamber.Figure 2 Schematic diagram of silicon molecular beam epitaxial system(1) electron beam bombardment of the surface of the silicon target, making it easy to produce silicon molecular beam. In order to avoid the radiation of the silicon molecular beam to the side to cause adverse effects, large area screen shielding and collimation is necessary.(2) resistance to heating the silicon cathode can not produce strong molecular beam, the other graphite citrus pots have Si-C stained, the best way is to electron beam evaporation to produce silicon source. Because, some parts of the silicon MBE temperature is higher, easy to evaporate, silicon low evaporation pressure requirements of the evaporation source has a higher temperature. At the same time, the beam density and scanning parameters to control. Making the silicon melting pit just in the silicon rod, silicon rods become high-purity citrus.There are several kinds of monitoring molecular beam:(1) Quartz crystal is often used to monitor beam current, beam shielding and cooling appropriate, can be satisfied with the results, but the noise affects the stability. After several μm, the quartz crystal loses its linearity. Frequent exchange, the main system is often inflated, which is not conducive to work.(2) small ion table, measured molecular beam pressure, rather than measuring the molecular beam flux. Due to the deposition on the system components leaving the standard.(3) low-energy electron beam, through the molecular beam, the use of electrons detected by the excitation fluorescence. The atoms are excited and quickly degrade to the ground state to produce uv fluorescence, and the optical density is proportional to the beam density after optical focusing. Do the feedback control of the silicon source. Inadequate: cut off the electron beam, most of the infrared fluorescence and background radiation will make the signal to noise ratio deteriorated to the extent of instability. It only measured atomic class, can not measure molecular substances.(4) Atomic absorption spectra, monitoring the beam density of doped atoms.With the intermittent beam current, Si and Ga were detected by 251.6nm and 294.4nm optical radiation respectively. The absorption intensity of the beam through the atomic beam was converted into atomic beam density and the corresponding ratio was obtained.Molecular beam epitaxy (MBE) substrate base is a difficult point.MBE is a cold wall process, that is, silicon substrate heating up to 1200 ℃, the environment to room temperature. In addition, the silicon wafer to ensure uniform temperature. Hill resistance refractory metal and graphite cathode, the back of the radiation heating, and the entire heating parts are installed in liquid nitrogen cooled containers, in order to reduce the thermal radiation of the vacuum components. The substrate is rotated to ensure uniform heating. Free deflection, can enhance the secondary implantation doping effect.

Источник: Meeyou Carbide