Specialized in carbide round bars, Meetyou Carbide manufacture and stock carbide rods for you.

We produce and stock all kinds of standard end mills for steel, aluminium, stainless steel, etc.

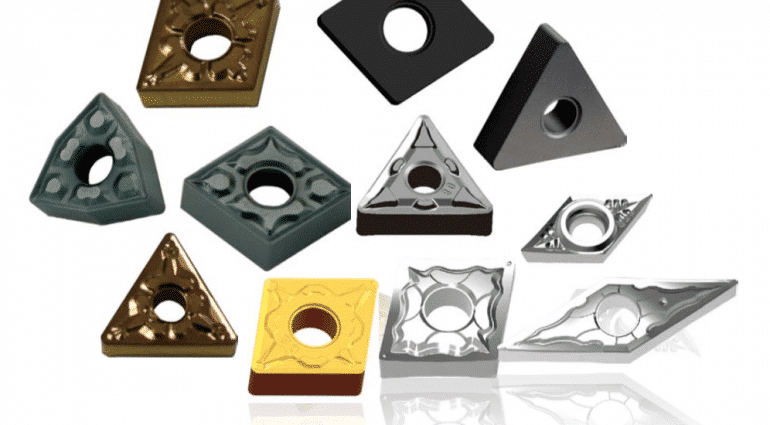

We manufacture and stock ISO carbide inserts for multiple applications.OEM is also accepted.

We provide cnc turning tools, including turning inserts and holder.

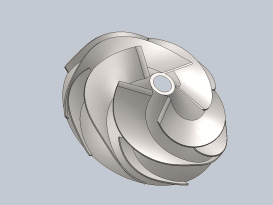

We offer carbide tool for milling, including milling inserts, cutters and end mills

We offer drilling inserts and solid drills.

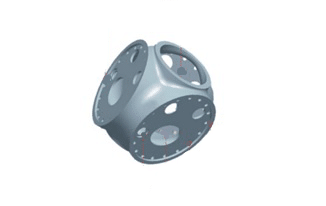

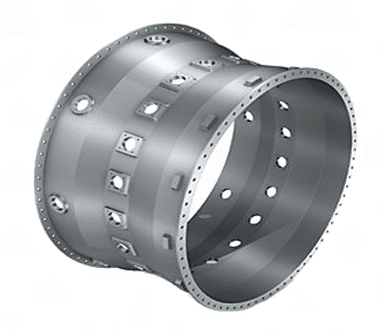

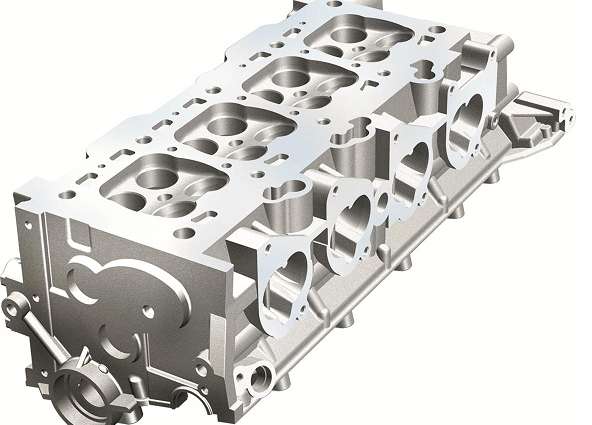

The cylinder head is one of the key components of aengine, with cova er mounting surface as the top surface, lower surface mating with upper surface on the cylinder body, exhaust pipe joint surface at two sides, front shroud in the front, transmission at the rear, respectively. All six surfaces are mating surface, requiring accurate dimension, perpendicularity with each other, good flatness and lower surface roughness.

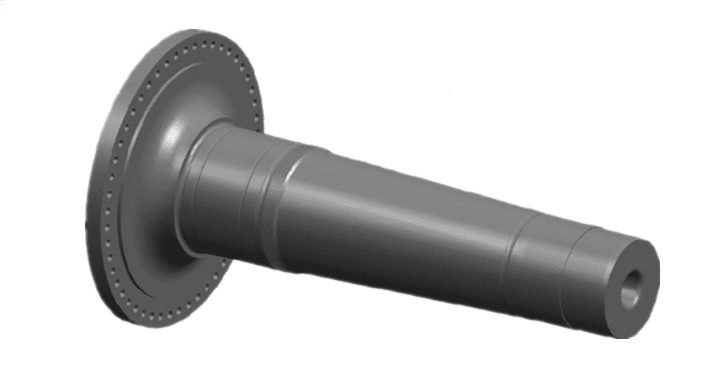

A crankshaft is made of carbon structural steel or nodular cast iron; it is the critical rotating part of the engine. When mounted with connecting rod,piston converts linear reciprocating motion into rotating motion. At present, the maximum revolving speed of automotive engine we are familiar with can reach 6000r/min above, which places more strict requirements on process technique including location consistency, circularity, and straightness of hole-centre of a different crankshaft, surface roughness, etc

As one of the biggest manufacturer here in Zhuzhou, we will provide you with the most competitive carbide cutting tool

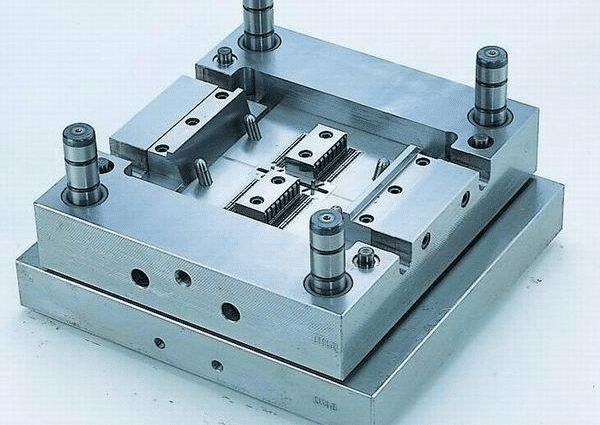

MCCT specializes in various types of CNC precision machining, including turning, grinding, milling, etc.