WE help you

Milling Like Dancing

What is CNC Milling

Milling refers to the use of a rotating multi-blade tool to cut a workpiece and is an efficient method of machining. When the tool rotates (master movement) during work, the workpiece moves (for feed motion), the workpiece can also be fixed, but at this time the rotating tool must also be moved (main movement and feed movement are completed at the same time). Milling machines include horizontal or vertical milling machines, as well as large portal milling machines. These machines can be ordinary machine tools or CNC machine tools. Use a rotating milling cutter as a cutting tool. Milling is generally performed on a milling or boring machine and is suitable for machining planes, grooves, various forming surfaces (eg flowers

Milling Milling Keys, gears, and threads) and special shapes of molds.

CNC lathes can be used to machine complex rotary bodies. Milling fixes the blank and uses a high-speed rotating cutter to advance the blank and cut out the desired shape and features. Traditional milling is used more for simple profile features such as milling profiles and slots. CNC milling machines can handle complex shapes and features. The boring and milling machining center can perform three-axis or multi-axis boring and boring machining for machining, dies, gauges, lathes, thin-walled complex surfaces, artificial prostheses, blades, etc. When selecting CNC milling processing content, the advantages and key functions of the CNC milling machine should be fully utilized.

A common metal cold processing method is different from turning in that the tool rotates at a high speed under the drive of the spindle in the milling process, and the processed workpiece is relatively stationary.

The difference between turning and milling:

Turning is used to process rotary parts. The part is clamped on the spindle of the machine tool by three chucks, and it is rotated at a high speed. Then, the turning tool is used to turn the part into the shape of the rotary body. Lathes can also be machined for bores, threads, biting flowers, etc. The latter two are low-speed machining.

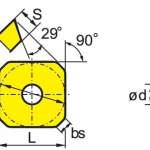

(1) Plane Parts

The characteristics of flat parts are represented in the processing surface can be parallel to the horizontal plane, but also perpendicular to the horizontal plane, can also be a fixed angle with the angle of the horizontal plane; most of the parts processed on the CNC milling machine are flat parts, flat parts are The simplest type of parts in the CNC milling process generally requires only two-axis or three-axis linkage of the three-axis CNC milling machine. In the machining process, the machined surface is in surface contact with the tool, and the end mill or bull nose can be used for both rough and finish machining.

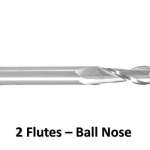

(2) Surface Parts

The feature of surface parts is that the machining surface is a space surface. In the machining process, the machining surface and the milling cutter are always in point contact. The surface finish is mostly done with a ball-end cutter.