Why is tungsten carbide an ideal tool material?

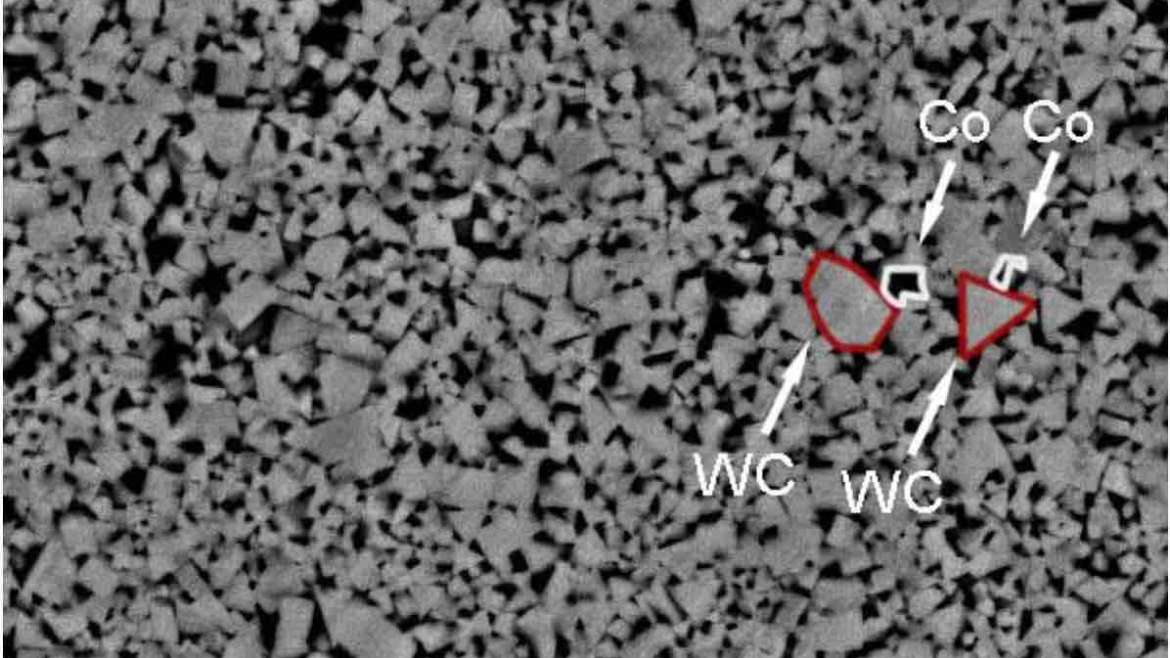

Tungsten carbide is the most widely used type of high-speed machining (HSM) tool material produced by powder metallurgy, consisting of hard carbide (usually tungsten carbide WC) particles and a softer metal bond. composition. At present, there are hundreds of WC-based tungsten carbides with different compositions, most of which use cobalt (Co) as a binder. Nickel (Ni) and chromium (Cr) are also commonly used binder elements, and other additives can be added. Some alloying elements.

Why are there so many carbide grades? How do tool manufacturers choose the right tool material for a particular cutting process? To answer these questions, let us first understand the various properties that make tungsten carbide an ideal tool material.

What is Tungsten carbide ?- the unity of hardness and toughness

WC-Co tungsten carbide has a unique advantage in both hardness and toughness. Tungsten carbide (WC) itself has a very high hardness (beyond corundum or alumina) and its hardness is rarely reduced as the operating temperature increases. However, it lacks sufficient toughness, which is an essential property for cutting tools. In order to take advantage of the high hardness of tungsten carbide and improve its toughness, metal binders are used to bond tungsten carbide so that the material has a hardness far exceeding that of high-speed steel while being able to withstand most cutting processes. Cutting force. In addition, it can withstand the high temperatures of cutting produced by high-speed machining.

Today, almost all WC-Co tools and inserts are coated, so the role of the matrix material seems less important. But in fact, it is the high modulus of elasticity of the WC-Co material (the measure of stiffness, the room temperature modulus of WC-Co is about three times that of high-speed steel) provides a non-deformable substrate for the coating. The WC-Co matrix also provides the required toughness. These properties are basic properties of WC-Co materials, but they can also be tailored to the material composition and microstructure when producing tungsten carbide powders. Therefore, the suitability of the tool performance to a particular process depends to a large extent on the initial milling process.

What is the milling process for tungsten carbide?

The tungsten carbide powder is obtained by carburizing the tungsten (W) powder. The properties of the tungsten carbide powder, especially its particle size, depend primarily on the particle size of the raw tungsten powder and the temperature and time of carburization. Chemical control is also critical, and the carbon content must be kept constant (close to the theoretical ratio of 6.13% by weight). In order to control the particle size by a subsequent process, a small amount of vanadium and/or chromium may be added before the carburizing treatment. Different downstream process conditions and different final processing applications require a combination of specific tungsten carbide particle size, carbon content, vanadium content, and chromium content, and variations in these combinations can produce a variety of different tungsten carbide powders.

When the tungsten carbide powder is mixed and ground with a metal bond to produce a certain grade of tungsten carbide powder, various combinations can be employed. The most commonly used cobalt content is 3% to 25% by weight, and nickel and chromium are required to increase the corrosion resistance of the tool. In addition, the metal bond can be further improved by adding other alloy components. For example, the addition of niobium to WC-Co tungsten carbide can significantly improve the toughness without lowering its hardness. Increasing the amount of binder can also increase the toughness of the tungsten carbide, but it will reduce its hardness.

Reducing the size of the tungsten carbide particles can increase the hardness of the material, but in the sintering process, the particle size of the tungsten carbide must remain unchanged. At the time of sintering, the tungsten carbide particles are combined and grown by the process of dissolution and re-precipitation. In the actual sintering process, in order to form a completely dense material, the metal bond is turned into a liquid state (referred to as liquid phase sintering). The growth rate of the tungsten carbide particles can be controlled by adding other transition metal carbides including vanadium carbide (VC), chromium carbide (Cr3C2), titanium carbide (TiC), tantalum carbide (TaC), and niobium carbide (NbC). These metal carbides are usually added during the mixing and milling of the tungsten carbide powder together with the metal binder, although vanadium carbide and chromium carbide can also be formed when carburizing the tungsten carbide powder.

Grades of tungsten carbide powder can also be produced from recycled solid carbide materials. The recycling and reuse of used tungsten carbide has a long history in the tungsten carbide industry and is an important part of the industry’s entire economic chain, helping to reduce material costs, conserve natural resources and avoid waste materials. Harmful disposal. Waste tungsten carbide can generally be reused by APT (ammonium paratungstate) process, zinc recovery process or by pulverization. These “recycled” tungsten carbide powders generally have better, predictable densification because their surface area is smaller than tungsten carbide powder made directly from the tungsten carburizing process.

The processing conditions for the mixing of tungsten carbide powder with a metal bond are also critical process parameters. The two most common milling techniques are ball milling and ultrafine milling. Both processes allow the milled powder to be evenly mixed and reduce particle size. In order to allow the workpiece to be pressed to have sufficient strength to maintain the shape of the workpiece and allow the operator or robot to pick up the workpiece for operation, it is usually necessary to add an organic binder during milling. The chemical composition of such a binder can affect the density and strength of the pressed workpiece. In order to facilitate the operation, it is preferable to add a high-strength binder, but this results in a lower pressing density and may cause a hard block, resulting in defects in the final product.

After the milling is completed, the powder is typically spray dried to produce a free flowing mass that is agglomerated by the organic binder. By adjusting the composition of the organic binder, the fluidity and charge density of these agglomerates can be tailored to suit the needs. By screening out coarser or finer particles, the particle size distribution of the agglomerates can be further tailored to ensure good fluidity when loaded into the mold cavity.

What is the manufacturing method of tungsten carbide workpieces?

Carbide workpieces can be formed by a variety of processes. Depending on the size of the workpiece, the level of shape complexity, and the production lot size, most cutting inserts are molded using a top and bottom pressure rigid mold. In order to maintain the consistency of the weight and size of the workpiece at each press, it is necessary to ensure that the amount of powder (mass and volume) flowing into the cavity is exactly the same. The fluidity of the powder is mainly controlled by the size distribution of the agglomerates and the characteristics of the organic binder. A molded workpiece (or “blank”) can be formed by applying a molding pressure of 10-80 ksi (kilopounds per square foot) to the powder loaded into the cavity.

Even at extremely high molding pressures, the hard tungsten carbide particles are not deformed or broken, and the organic binder is pressed into the gap between the tungsten carbide particles, thereby functioning to fix the particle position. The higher the pressure, the tighter the bond of the tungsten carbide particles and the greater the compaction density of the workpiece. The molding properties of the graded tungsten carbide powder may vary, depending on the amount of metal binder, the size and shape of the tungsten carbide particles, the extent to which the agglomerates are formed, and the composition and amount of organic binder. In order to provide quantitative information on the pressing characteristics of the grade of tungsten carbide powder, it is usually designed by the powder manufacturer to establish the correspondence between the molding density and the molding pressure. This information ensures that the supplied powder is in line with the toolmaker’s molding process.

Large-size carbide workpieces or carbide workpieces with high aspect ratios (such as end mills and drill bit shanks) are typically manufactured by uniformly pressing the tungsten carbide powder in a flexible bag. Although the production cycle of the equalization pressing method is longer than the molding method, the manufacturing cost of the tool is lower, so the method is more suitable for small batch production.

This process involves charging the powder into a bag and sealing the mouth of the bag, then placing the bag filled with the powder in a chamber and applying a pressure of 30-60 ksi by a hydraulic device for pressing. Pressed workpieces are typically machined to specific geometries prior to sintering. The size of the bag is increased to accommodate shrinkage of the workpiece during the compaction process and to provide sufficient allowance for the grinding process. Since the workpiece is processed after press forming, the requirements for consistency of the charge are not as strict as the molding method, but it is still desirable to ensure that the amount of powder per load is the same. If the loading density of the powder is too small, the powder loaded into the bag may be insufficient, resulting in a small workpiece size and having to be scrapped. If the loading density of the powder is too large, the powder loaded into the bag is too much, and the workpiece needs to be processed to remove more powder after press forming. Although the excess powder and scrapped parts can be recycled, this will reduce productivity.

Carbide workpieces can also be formed by extrusion or injection molding. The extrusion process is more suitable for mass production of axisymmetric shaped workpieces, while the injection molding process is commonly used for mass production of complex-shaped workpieces. In both molding processes, the grade of tungsten carbide powder is suspended in an organic binder that imparts uniformity to the tungsten carbide mixture like toothpaste. The mix is then either extruded through a hole or molded into a mold cavity. The characteristics of the grade of tungsten carbide powder determine the optimum ratio of powder to the binder in the mix and have an important effect on the flow of the mixture through the extrusion orifice or into the mold cavity.

After the workpiece is formed by molding, equalization pressing, extrusion or injection molding, the organic binder needs to be removed from the workpiece before the final sintering stage. Sintering removes the pores in the workpiece, making it completely (or substantially) dense. At the time of sintering, the metal bond in the press-formed workpiece becomes a liquid, but the workpiece can still maintain its shape under the combined action of capillary force and particle contact.

After sintering, the geometry of the workpiece remains the same, but the size shrinks. In order to obtain the required workpiece size after sintering, the shrinkage rate needs to be considered when designing the tool. When designing the grade of tungsten carbide powder used to make each tool, it must be ensured that it has the correct shrinkage when pressed under the appropriate pressure.

In almost all cases, the sintered workpiece which is also called as carbide blank needs to be post-sintered. The most basic treatment for cutting tools is sharpening the cutting edge. Many tools require grinding and geometry of their geometry after sintering. Some tools require grinding of the top and bottom; others require peripheral grinding (with or without sharpening the cutting edge). All carbide wear debris from grinding can be recycled.

How to prepare the workpiece coating of tungsten carbide?

In many cases, the finished part needs to be coated. The coating provides lubricity and increased hardness, and provides a diffusion barrier to the substrate that prevents oxidation when exposed to high temperatures. The tungsten carbide matrix is critical to the performance of the coating. In addition to the main characteristics of the custom matrix powder, the surface properties of the substrate can be tailored by chemical selection and modification of the sintering process. Through the migration of cobalt, more cobalt can be enriched in the outermost layer of the blade surface in the thickness of 20-30 μm relative to the rest of the workpiece, thereby imparting better toughness to the surface layer of the substrate, so that it has strong resistance to deformation.

Tool manufacturers based on their own manufacturing processes (such as dewaxing methods, heating rates, sintering times, temperatures, and carburizing voltages) may impose special requirements on the grades of carbide powder used. Some toolmakers may sinter workpieces in vacuum furnaces, while others may use hot isostatic pressing (HIP) sintering furnaces (which pressurize the workpiece near the end of the process cycle to eliminate any residue). Pore). The workpiece sintered in the vacuum furnace may also need to be subjected to a hot isostatic pressing process to increase the workpiece density. Some tool manufacturers may use higher vacuum sintering temperatures to increase the sintered density of mixtures with lower cobalt content, but this approach may make the microstructure coarse. In order to maintain a fine grain size, a powder having a smaller tungsten carbide particle size may be used. In order to match the specific production equipment, dewaxing conditions and carburizing voltage also have different requirements on the carbon content of the tungsten carbide powder.

All of these factors have a critical impact on the microstructure and material properties of the tungsten carbide tool that is sintered. Therefore, there is a need for close communication between the tool manufacturer and the powder supplier to ensure that it is manufactured according to the tool. Customized production process custom grade tungsten carbide powder. Therefore, it is not surprising that there are hundreds of different carbide grades. For example, ATI Alldyne produces more than 600 different powder grades, each of which is specifically designed for the intended user and specific use.

What is the classification method for tungsten carbide grades?

The combination of different types of tungsten carbide powder, mixture composition and metal binder content, type and amount of grain growth inhibitors, etc., constitutes a variety of carbide grades. These parameters will determine the microstructure and properties of the tungsten carbide. Certain specific performance combinations have become the first choice for specific processing applications, making it possible to classify multiple carbide grades.

The two most commonly used carbide machining classification systems for machining purposes are the C grade system and the ISO grade system. Although neither of these systems fully reflects the material properties that affect the choice of carbide grades, they provide a starting point for discussion. For each taxonomy, many manufacturers have their own special grades, resulting in a wide variety of carbide grades.

Carbide grades can also be classified by composition. Tungsten carbide (WC) grades can be divided into three basic types: simple, microcrystalline and alloy. Simple grades consist primarily of tungsten carbide and cobalt binders, but may also contain small amounts of grain growth inhibitors. The microcrystalline grade consists of tungsten carbide and a cobalt binder with a few thousandths of vanadium carbide (VC) and/or chromium carbide (Cr3C2) added, and its grain size can be less than 1 μm. The alloy grade consists of tungsten carbide and a cobalt binder containing several percent of titanium carbide (TiC), tantalum carbide (TaC) and niobium carbide (NbC). These additives are also called cubic carbides because of their sintering. The resulting microstructure exhibits a non-uniform three-phase structure.

(1) Simple carbide grade

Such grades for metal cutting typically contain 3%-12% cobalt (by weight). The size of the tungsten carbide grains is usually in the range of 1-8 μm. As with other grades, reducing the particle size of tungsten carbide increases its hardness and transverse rupture strength (TRS), but reduces its toughness. The hardness of simple grades is usually between HRA 89-93.5; the transverse rupture strength is usually between 175-350 ksi. Such grades of powder may contain a large amount of recycled raw materials.

Simple grades can be divided into C1-C4 in the C grade system and can be classified according to the K, N, S and H grade series in the ISO grade system. Simple grades with intermediate characteristics can be classified as general grades (eg C2 or K20) for turning, milling, planing and boring; grades with smaller grain sizes or lower cobalt content and higher hardness can be used Classified as a finishing grade (such as C4 or K01); grades with larger grain sizes or higher cobalt content and better toughness can be classified as rough grades (eg C1 or K30).

Tools made from simple grades can be used to cut cast iron, 200 and 300 series stainless steel, aluminum and other non-ferrous metals, superalloys and hardened steel. These grades can also be used in non-metal cutting applications (such as rock and geological drilling tools) with grain sizes ranging from 1.5 to 10 μm (or larger) and cobalt levels from 6% to 16%. Another non-metal cutting type of simple carbide grades is the manufacture of molds and punches. These grades typically have a medium size grain size with a cobalt content of 16%-30%.

(2) Microcrystalline carbide grade

Such grades usually contain 6%-15% cobalt. In the liquid phase sintering, the added vanadium carbide and/or chromium carbide can control the grain growth, thereby obtaining a fine grain structure having a particle size of less than 1 μm. This fine grain grade has a very high hardness and a transverse rupture strength of 500 ksi or more. The combination of high strength and sufficient toughness allows these grades of tools to have a larger positive rake angle, which reduces cutting forces and produces thinner chips by cutting rather than pushing metal.

Through the strict quality identification of various raw materials in the production of grades of tungsten carbide powder and strict control of the sintering process conditions, it is possible to prevent the formation of abnormal large grains in the microstructure of the material. Material properties. In order to keep the grain size small and uniform, the recycled powder can only be used if the raw materials and recovery process are fully controlled and extensive quality testing is performed.

Microcrystalline grades can be classified according to the M grade series in the ISO grade system. In addition, the other classification methods in the C grade system and the ISO grade system are the same as the simple grades. Microcrystalline grades can be used to make tools for cutting softer workpiece materials because the surface of the tool can be machined very smoothly and maintain an extremely sharp cutting edge.

Microcrystalline grades can also be used to machine nickel-based superalloys because they can withstand cutting temperatures up to 1200 °C. For the processing of high-temperature alloys and other special materials, the use of micro-grain grade tools and simple grade tools with enamel can simultaneously improve their wear resistance, deformation resistance and toughness. Microcrystalline grades are also suitable for making rotary tools (such as drill bits) that generate shear stress. One type of drill bit is made of a composite grade of tungsten carbide. The specific cobalt content of the material in the specific part of the same bit is different, so that the hardness and toughness of the drill bit are optimized according to the processing needs.

(3) Alloy type carbide grade

These grades are mainly used for cutting steel parts, which typically have a cobalt content of 5%-10% and a grain size range of 0.8-2 μm. By adding 4% to 25% of titanium carbide (TiC), the tendency of tungsten carbide (WC) to diffuse to the surface of the steel scrap can be reduced. Tool strength, crater wear resistance and thermal shock resistance can be improved by adding no more than 25% tantalum carbide (TaC) and niobium carbide (NbC). The addition of such cubic carbides also increases the redness of the tool, helping to avoid thermal deformation of the tool during heavy-duty cutting or other machining where the cutting edge can create high temperatures. In addition, titanium carbide can provide nucleation sites during sintering, improving the uniformity of cubic carbide distribution in the workpiece.

In general, alloy-type carbide grades have a hardness range of HRA91-94 and a transverse rupture strength of 150-300 ksi. Compared with the simple type, the wear resistance of the alloy type has poor wear resistance and low strength, but its bond wear resistance is better. Alloy grades can be divided into C5-C8 in the C grade system, and can be classified according to the P and M grade series in the ISO grade system. Alloy grades with intermediate properties can be classified as general grades (eg C6 or P30) for turning, tapping, planing and milling. The hardest grades can be classified as fine grades (eg C8 and P01) for finishing and boring. These grades typically have a smaller grain size and a lower cobalt content to achieve the desired hardness and wear resistance. However, similar material properties can be obtained by adding more cubic carbides. The most resilient grades can be classified as rough grades (eg C5 or P50). These grades typically have a medium size particle size and a high cobalt content, and the amount of cubic carbide added is also small to achieve the desired toughness by inhibiting crack propagation. In the interrupted turning process, the cutting performance can be further improved by using the cobalt-rich grade having a higher cobalt content on the surface of the cutter.

Alloy grades with low titanium carbide content are used for machining stainless steel and malleable cast iron, but can also be used to process non-ferrous metals (such as nickel-based superalloys). These grades typically have a grain size of less than 1 μm and a cobalt content of 8% to 12%. Grades with higher hardness (eg M10) can be used for turning malleable cast iron; grades with better toughness (eg M40) can be used for milling and planing steel or for turning stainless steel or superalloys.

Alloy-type carbide grades can also be used for non-metal cutting applications, primarily for the manufacture of wear-resistant parts. These grades typically have a particle size of 1.2-2 μm and a cobalt content of 7%-10%. In the production of these grades, a large proportion of recycled materials are usually added, resulting in higher cost-effectiveness in the application of wear parts. Wear parts require good corrosion resistance and high hardness. These grades can be obtained by adding nickel and chromium carbide when producing such grades.

In order to meet the technical and economic requirements of tool manufacturers, tungsten carbide powder is a key element. Powders designed for toolmakers’ processing equipment and process parameters ensure the performance of the finished part and result in hundreds of carbide grades. The recyclable nature of carbide materials and the ability to work directly with powder suppliers allows tool manufacturers to effectively control their product quality and material costs.

Dedicated to the top quality china carbide cutting tool, we help you better turning, milling and drilling for greater cost-effectiveness.

Our products mainly include