Top China Carbide Inserts

Things You Should Know About Carbide Inserts

If your work involves any form of metal cutting, you’ll almost certainly have heard about carbide inserts at one stage or another. However, a limited knowledge on the subject may leave you wondering what they can be used for and whether they are actually a necessary investment for your operation.

Here’s all you need to know about carbide inserts and how they can be used for within your metal work processes.

What are Carbide Inserts?

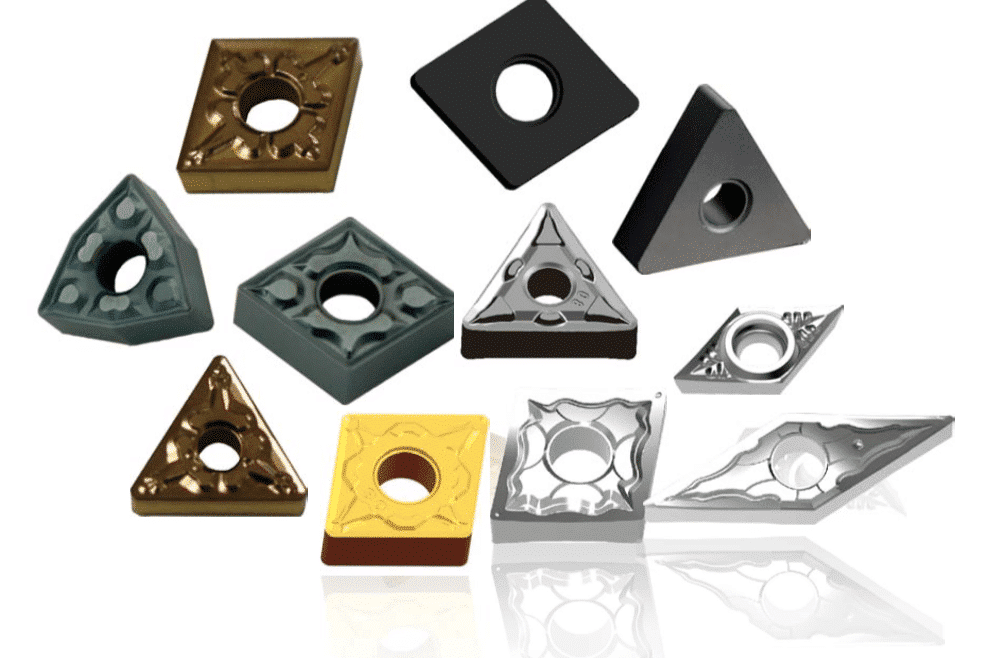

Carbide inserts are small bits of cemented carbide that are commonly used in lathes and milling machines. They can be used in machining steels, cast iron, high-temperature alloys, and nonferrous materials.

Inserts are tooltips and their main use is to help cut metal materials into the desired geometric shape. This is commonly done by using the lathe but can be achieved through other metal work processes.

The bits are replaceable and can be used as turning inserts, milling inserts, and drilling inserts. The cemented carbide is commonly a combination of tungsten carbide and cobalt. Inserts created with hard materials (1 micron or lower) will be hard wearing but brittle while soft materials (3 microns or higher) will be softer wearing.

As such, you’ll need to think about the strength and toughness needed for your specific job. After all, carbide inserts are used for virtually all metalwork and lathe projects. In fact, you could go through dozens each day.

indexable inserts can also be used in surgical tools, jewellery tools, and a host of other materials.

Benefits of Carbide Inserts

indexable inserts are a useful addition to any workshop or factory that uses metal work processes. Some of their uses have been mentioned above. Here are five reasons why they are essential:

- Available in many options and can be used for a host of necessary metalwork procedures.

- Provide a better finish on your metal work products while also giving you greater control in the process.

- Withstand greater temperatures than steel tools, providing greater protection and reliability.

- Allow for faster work, speeding up the production process without compromising on quality.

- Very cheap, making them an even greater investment in your working environment.

Furthermore, by choosing MCCT for your carbide inserts, you’ll be guaranteed to receive the best quality and most reliable units time and time again.

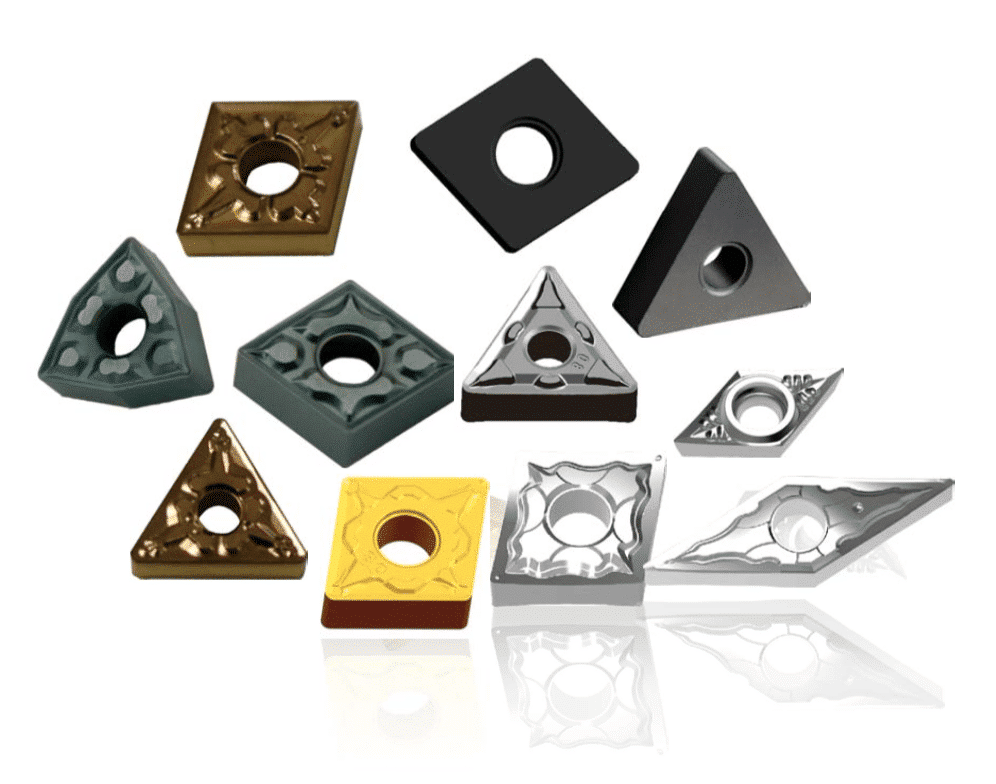

What Shapes are Available?

Carbide inserts are very versatile and are available in several shapes and sizes. The list of shapes includes, but is not limited to:

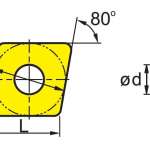

- Diamond (available at different angles)

- Hexagon

- Octagon

- Parallel milling inserts

- Round

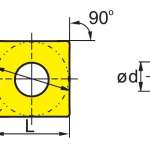

- Square

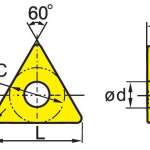

- Triangular

- Tangential milling inserts

- Trigons

Meanwhile, grooving/threading/parting inserts and drilling inserts can be purchased. This range of products can ultimately help you with all your metalwork activities.

Conclusion

Carbide inserts may only be small, but they can make a huge impact on your productivity. As top China carbide manufacturer in Zhuzhou, we produce and stock ISO carbide inserts for multiple applications.OEM is also accepted as per your requirements.