What can you think of when it comes to welding?

Fire heart splashing? High temperature and high heat? Flashing eyes?

No matter what you think of, you are not likely to think of our furniture anyway, nor will it be associated with wood. Why? Because you will feel welded wood, it is not a matter of “fueling on fire”, who makes our favorite wood most afraid of heat and fire.

Ok! You are right, if it is like a traditional welding technique, holding a welding torch and squirting between two pieces of wood, I am afraid I have to call 119 for a fire.

However, the welding we are going to say today is indeed applied to the connection of wood products, but unlike the common iron welding requires the introduction of ultra-high heat sources. What is mysterious technology? Don’t worry, this article introduces you to the “round bar rotating wood welding technology.”

Is the current wood product connection method not good?

of course not! The production and assembly technology of solid wood furniture has developed to maturity and stability, but there is still room and room for improvement.

The traditional tantalum joint production process is complicated and the wood loss is serious; the metal parts in the metal parts are prone to rust spots or corrosion and affect the strength of the joint; the round rods are joined and must be coated in the bore or on the raft during assembly. Glue, so there is a situation in which the glue is easy to contaminate the non-joined surface, and certain pollutants are released during production and use.

The round bar rotating wood welding technology we are talking about is a new technology developed from Europe at the end of the 20th century and the beginning of the 21st century. The round bar is in the pre-drilled round hole (the diameter of the hole is larger than the diameter of the round bar). Slightly small) high-speed rotation without any adhesive or any other material, fixed in the holed wood substrate or relatively fixed substrate, is a momentary joint, economical, environmentally friendly, and promising Wood joining technology.

In the end, what is the round bar rotating wood welding?

How to define this technology? Related scholars describe it as follows: without adding any adhesive, the high-speed rotating round bar is frictionally bonded to the wood substrate in an instant (2-4 seconds) and has a certain strength of connection technology, called a round bar. Rotating wood welding.

Focusing on the “high-speed rotation”, “friction”, “instant engagement” is undoubtedly the characteristics of the technology, but still do not understand: Why can we achieve the so-called “welding”?

The principle is this:

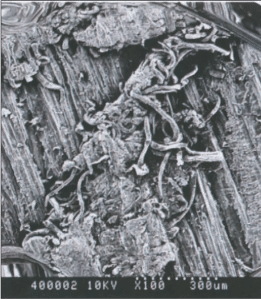

The round bar is rotated at high speed into the pupil. During the contact interface, th e round bar and the inner wall of the bore are rubbed to generate high temperature. The high molecular polymer (mainly lignin and some hemicellulose) in the amorphous region of the wood fiber is softened. Melting, and the fibers form an entangled net, which is fused in the molten wood polymer. When the round bar stops rotating, it cools and solidifies to form a welded strip and is connected together.

e round bar and the inner wall of the bore are rubbed to generate high temperature. The high molecular polymer (mainly lignin and some hemicellulose) in the amorphous region of the wood fiber is softened. Melting, and the fibers form an entangled net, which is fused in the molten wood polymer. When the round bar stops rotating, it cools and solidifies to form a welded strip and is connected together.

It can be seen from the above figure that the microscopic welds of the welded strips are intertwined and connected. When the friction welding of the wood is completed, the “new interface” lignin and hemicellulose (furfural, xylan) are formed into a polymerization and cross-linking chemical reaction. Therefore, after the round bar stops rotating, in order to ensure a certain joint strength, it is necessary to maintain a certain instantaneous pressure.