lo que ofrecemos

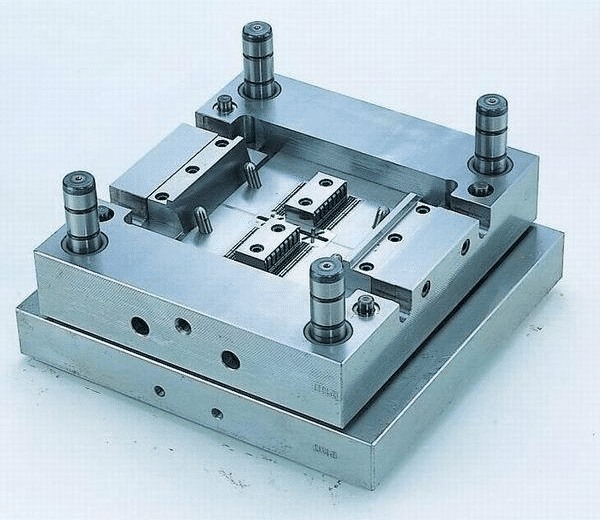

Nuestros servicios

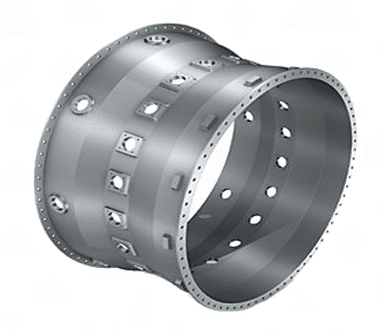

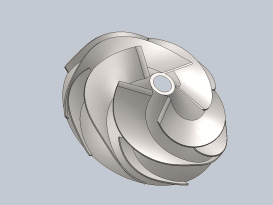

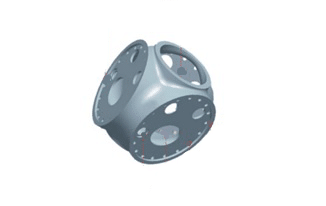

Herramientas que suministramos

El poder

Una fuerza global en la producción e ingeniería de herramientas de corte de carburo

Como ayudamos

Aplicación tipica

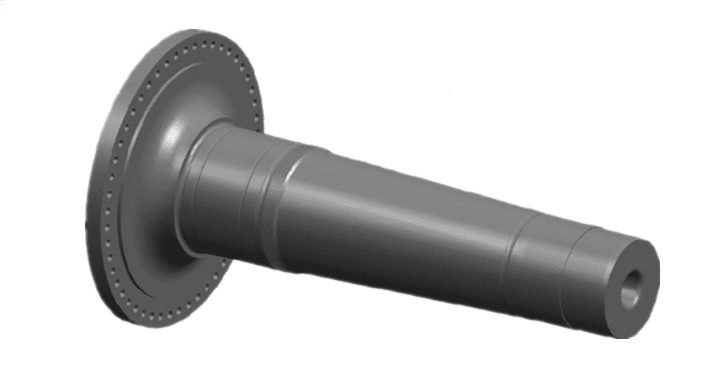

Un cigüeñal está hecho de acero al carbono estructural o fundición nodular; Es la parte giratoria crítica del motor. Cuando se monta con biela, el pistón convierte el movimiento recíproco lineal en un movimiento giratorio. En la actualidad, la velocidad máxima de rotación del motor automotriz con la que estamos familiarizados puede alcanzar 6000r / min, lo que impone requisitos más estrictos en la técnica del proceso, incluida la consistencia de ubicación, la circularidad y la rectitud del centro del orificio de un cigüeñal diferente, la rugosidad de la superficie, etc.

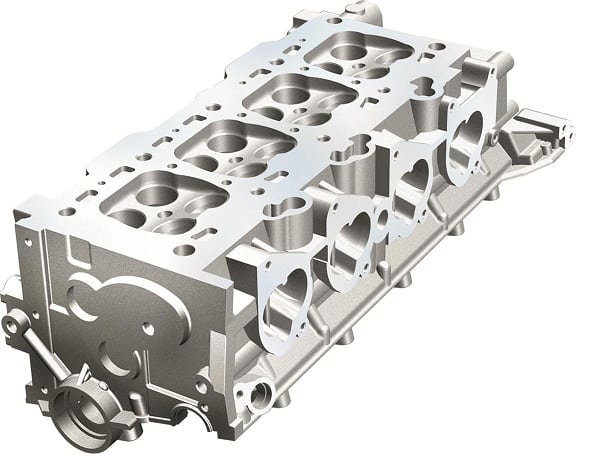

La culata es uno de los componentes clave de un motor, con una superficie de montaje de cova como la superficie superior, la superficie inferior se acopla con la superficie superior en el cuerpo del cilindro, la superficie de la junta del tubo de escape en dos lados, la cubierta frontal en la parte delantera, la transmisión en la parte delantera. trasero, respectivamente. Las seis superficies son superficies de acoplamiento, que requieren una dimensión precisa, perpendicularidad entre sí, buena planitud y menor rugosidad de la superficie.