In der täglichen Produktion wirkt sich die vernünftige Wahl des Drehwerkzeugmaterials und der Form direkt auf die Arbeitsproduktivität und die Bearbeitungsqualität der Teile aus. Beim Schneiden muss das Werkzeug viel Schnittkraft und Schlag aushalten …

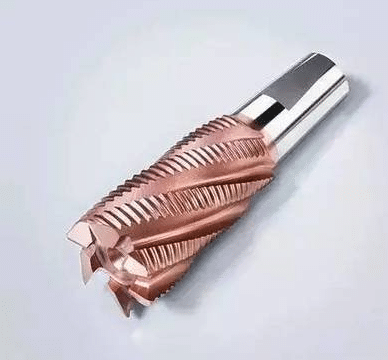

In dieser Werkzeugwoche konzentrieren wir uns auf das Wissen über die Beschichtung von Hartmetallwerkzeugen. Willkommen beim Stöbern in Beschichtungswerkzeugen unseres Unternehmens. Art der Beschichtung Titannitrid (TiCN) Die Härte der Beschichtung ist höher als die der TiN-Beschichtung. Aufgrund der…

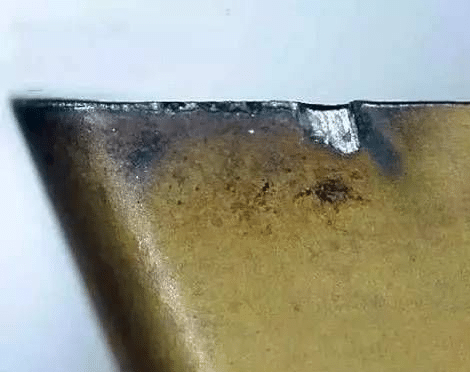

Die Fehlersuche beim Bearbeitungsvorgang ist eine schwierige Aufgabe, insbesondere bei Bohrprozessen. Die Gründe dafür sind folgende: Bei der Bearbeitung für das Außenteil sieht man die Ursachen des Werkzeugausfalls: aber wenn das Werkzeug…

In our daily life, no matter in small tableware or decoration, stainless steel processing is more and more widely used. So what should we pay attention to in the key points of stainless steel processing? Next, let’s have a brief…

Maybe you’ve heard people should never ever drill a hole with an end mill if there isn’t already a hole at the center for the chips to clear. Why can’t the end mill clear the chips? If the answer is no. How…

What Should You Know about Parting Tools and Parting Operation Parting is to insert a blade like tool directly into the workpiece and cut off the workpiece with a certain length. It is usually used to remove the finished end…

Fixture design is generally carried out in accordance with the specific requirements of a certain process after the formulation of the machining process of parts. The possibility of fixture realization should be fully considered in the formulation of process. When…

Reducing CO2 greenhouse gas emissions has become the goal of the world, and now many places are discussing to levy CO2 emission tax. Due to the emergence of new fields, and people have to adapt to the existing fields, the…

The power consumption in the process of metal cutting is expressed in the form of cutting heat and friction. These factors make the tool in bad machining conditions, with high surface load and high cutting temperature. The reason for high…

Titanium alloy and aluminum alloy are similar in the following aspects: both metals are used to manufacture aircraft structural parts, in which case 90% of the materials may need to be ground off before the parts are completed. Many stores…

If you don’t have a lot of experience in metalworking, you may not be familiar with this type of metal forming. How does it work and when do we use it? What is a turret punch? Turret punch, also known…

Cemented carbide has the edge of high hardness, good wear resistance, corrosion resistance and a small coefficient of thermal expansion. It is widely used in the manufacture of precision molds such as optical glass forming, metal drawing, and wear-resistant and corrosion-resistant…

High precision CNC lathe paired with advanced cutting tool provides us with superior material removal rate and productivity. As the connector between lathe and cutting tools, tool handle plays an important role in obtaining desired results. So how to choose…

As is well known to us, tipped cutting tools can be grouped into solid tool, brazed tool, tool with mechanical clamp, and tool with indexable tips on basis of methods to inlay tips on the tools. We herein discuss which makes up indexable inserts the…

The systematic mechanical related deviation of machine tool can be recorded by the system, but due to environmental factors such as temperature or mechanical load, the deviation may still appear or increase in the subsequent use process. In these cases,…