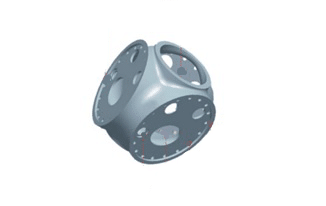

The wheel hub is the joint that connects rotor blades and is attached to the low-speed shaft of the wind turbine.

It’s one of the important parts of wind turbines, with complex structure and stress deformation. It directly affects the operation and service life of the wind turbine, so it requires high strength, good reliability, long fatigue life, and strong vibration absorption so as to meet the working condition from – 40 to – 20 ℃. It is often made of as-cast ductile iron with low temperature and high impact toughness. The major types of wheel hub machining are milling, boring and drilling.

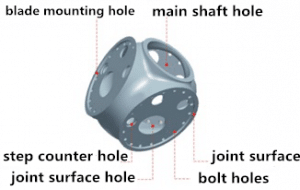

1.mounting hole of blade

2.main shaft hole

3.step counter hole on joint surface of blade

4.holes on joint surface of blade

5.joint surface of blade

6.bolt holes on joint surface of blade

A collet clamping system permits both sides of the hub to be finished—the bearing surface of the shoulder, as well as the rotor face, the rotor undercut and the rotor diameters.

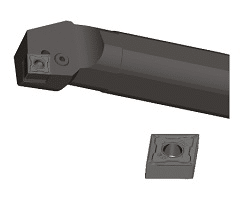

Turning main shaft hole—Internal turning tool

The use of internal hole turning tool on the vertical lathe for main shaft hole can greatly improve machining efficiency. A new generation of cast iron insert material. We keep improving the cutting efficiency of nodular cast iron, with a long service life of inserts and improved safety and reliability. Inserts with wiper can greatly improve finish turning without sacrificing surface quality.

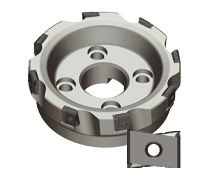

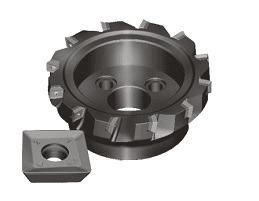

Rough milling blade joint surface

Special design of curved rake face effectively reduces cutting force and can be applied at a high feed, with high machining efficiency;

Vertically mounted inserts, suitable for large cutting depth and heavy-duty machining, can quickly remove the excess material of workpiece blank, improve the efficiency of rough machining;

Entering angle is 90 degrees, suitable for square shoulder milling.

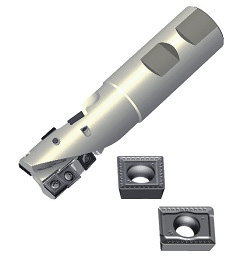

Finish milling blade joint surface

Entering angle is 90 degrees. This cutter can be applied for square shoulder milling with high precision.

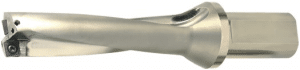

Milling blade mounting hole

The design concept of balancing edge security and sharpness ensures smooth cutting force is smooth and high safety under large cutting depth.

Boring blade joint face system

New boring cutter system includes modular boring cutter, modular digital display boring cutter, large diameter boring cutter, with wide boring range, suitable for all sorts of rough and fine boring in a variety of materials.

Drill blade joint face bolt hole

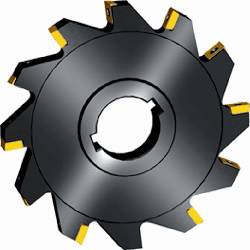

Interpolation reverse milling blade joint face step counterboring —— Face and side milling cutter