クランクシャフトは、炭素鋼またはノジュラー鋳鉄製です。それはエンジンの重要な回転部分です。コネクティングロッドを装着した場合、ピストンは直線往復運動を回転運動に変換します。現在、私たちが慣れ親しんでいる自動車エンジンの最高回転速度は上記の6000r / minに達することができ、それは場所の一貫性、真円度、および異なるクランクシャフトの穴中心の真直度、表面粗さなどを含むプロセス技術により厳しい要件を課します。

クランクシャフトは、炭素鋼またはノジュラー鋳鉄製です。それはエンジンの重要な回転部分です。コネクティングロッドを装着した場合、ピストンは直線往復運動を回転運動に変換します。現在、私たちが慣れ親しんでいる自動車エンジンの最高回転速度は上記の6000r / minに達することができ、それは場所の一貫性、真円度、および異なるクランクシャフトの穴中心の真直度、表面粗さなどを含むプロセス技術により厳しい要件を課します。

End-face machining

FMA07 series face milling cutter, octagon insert with 16 cutting edges, comb ined with excellent “black diamond ”grade, can achieve super-high economical efficiency and working efficiency.

ined with excellent “black diamond ”grade, can achieve super-high economical efficiency and working efficiency.

External turning

Insert edges has stepped appearance, external turning and step machining can be performed in one operation, greatly decrease the turning time and improve working efficiency.

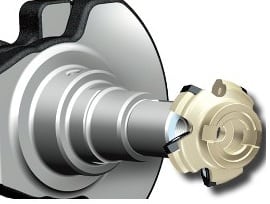

Crankshaft external milling

Teeth distribution in radial and axial direction can realize three side machining, more teeth involved in cutting, greatly improving the working stability and high efficiency.

Inclined oil hole machining

Convex milling: Solid carbide four flutes flattened endmill with straight shank, high stability edge treatment and high-rigidity structure design can realize multiple-functions of machining.

Inclined oil hole-making: combined with special coating grade, optimized structure design can achieve high-efficiency drilling machining.

Center countersink machining

ZTD series U drill, good mounting angle, optimized internal structure and firm drill

so the body can achieve high stable machining while bearing higher feed rate.

Flange hole-machining

Drilling: Solid carbide step drill, suitable for different high-precision drilling, can provide tailormade drills as per customer requirements.

Drilling: Solid carbide step drill, suitable for different high-precision drilling, can provide tailormade drills as per customer requirements.

Tapping: Newly solid carbide taps and forming taps, according to different materials features, we design the products to meet different working conditions and machining requirements.