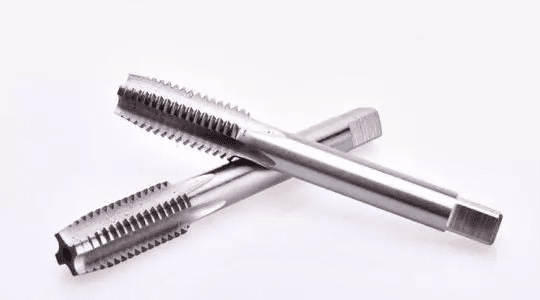

Teach you how to quickly identify the pros and cons of taps! There are many taps on the market. Because of the different materials used, the price of the same specification is also quite different, so that the purchaser looks…

Why is tungsten carbide an ideal tool material? Tungsten carbide is the most widely used type of high-speed machining (HSM) tool material produced by powder metallurgy, consisting of hard carbide (usually tungsten carbide WC) particles and a softer metal bond.…

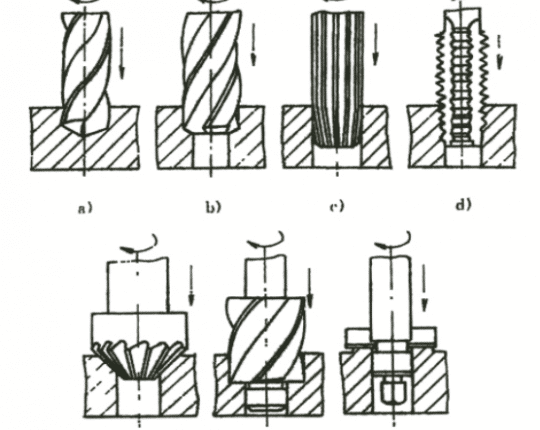

Drilling machine is a machine tool for machining internal holes. It is used to machine holes in solid materials. It is mainly used for machining workpieces with complex shapes and without symmetrical rotation axes, such as single holes on parts…

1. 1 cathode materialLithium-ion battery cathode materials are mainly divided into lithium-rich manganese-based materials, ternary composite materials, spinel-type LiMn 2 O 4 , lithium iron phosphate and lithium nickel manganese oxide. Li-rich manganese-based solid solution cathode material Li 1 +…

I. OverviewCemented carbide is also known as the “teeth” of the industry. Since its inception, as an efficient tool material and structural material, its application field has been continuously expanded, which has played an important role in promoting industrial development…

AbstractTurning cutting is lathe processing and lathe machining is part of machining. The Turning cutting machine mainly uses a Turning cutting tool to turn the rotating workpiece. On the lathe, drills, reamer, reamer, taps, dies and knurling tools can also…

CNC lathe machining is a kind of high-precision, high-efficiency machine tool with digital information control parts and tool displacement. It is an effective way to solve the problems of aerospace products, such as parts variety, small batch, complex shape, high…

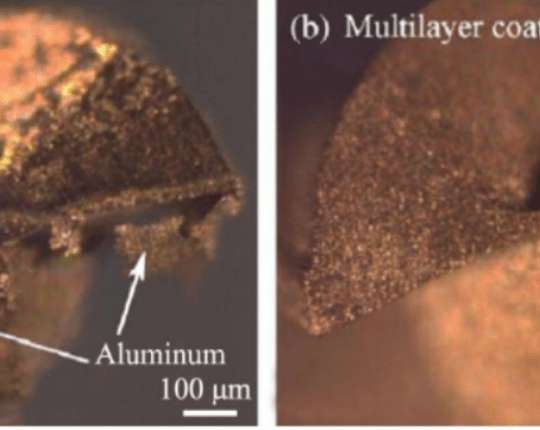

1. CVD Diamond Introduction Chemical Vapor Deposition (CVD) diamond refers to the use of CVD method, under low pressure conditions, with carbon-containing gases such as H2 and CH4 as the reaction gas, chemical reactions under plasma-assisted and certain temperature conditions,…

Cemented carbide is a composite material composed of high-hardness refractory metal carbides and cemented metals. Because of its high hardness, wear resistance, and stable chemical properties, it is used in modern tool materials and wear-resistant materials. High temperature and corrosion…

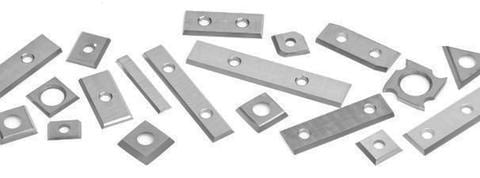

Machining is one of the most basic, widest and most important processes in the wood industry, directly affecting production efficiency, processing costs and energy consumption. With the advancement of the wood industry technology, various wood composite materials, plywood, wood, bamboo…

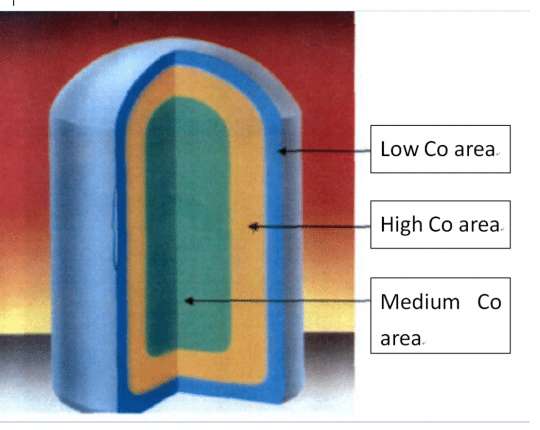

1. The contradictory characteristics of traditional uniform carbideCemented carbide is a typical brittle material. The traditional uniform carbide one, the material of the various parts of the uniform composition and organization, the alloy is homogeneous throughout, its performance is consistent.…

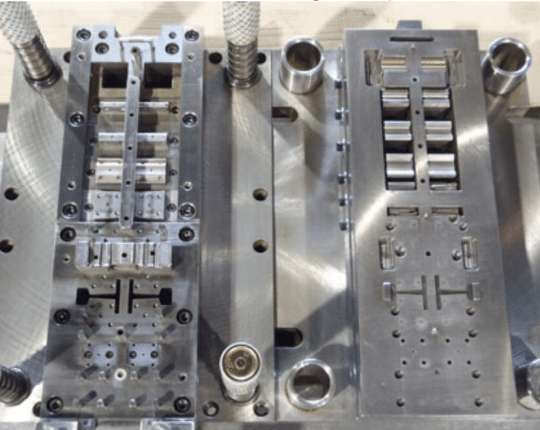

The progressive die is composed of multiple stations. Each station is connected in sequence to complete different processes. A series of different stamping processes are completed in one stroke of the press.1.OverviewProgressive die (also called continuous die) is composed of…

Cemented carbide(hardmetal) is a general term for alloys composed of carbides, nitrides, borides, or silicides of high melting point metals (W, Mo, Ti, V, Ta, etc.). Divided into two major categories of casting and sintering. The cast alloy has high…

RollerContinuously plastically deformed main working parts and tools on the rolling mill. The roller consists of a roller body, a roll neck and a shaft head. The roll body is the middle part of the roll that actually participates in…

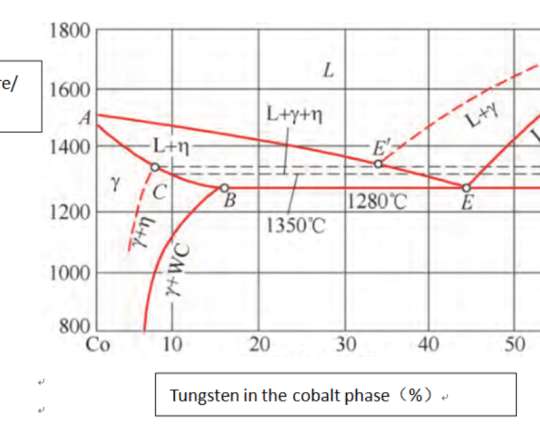

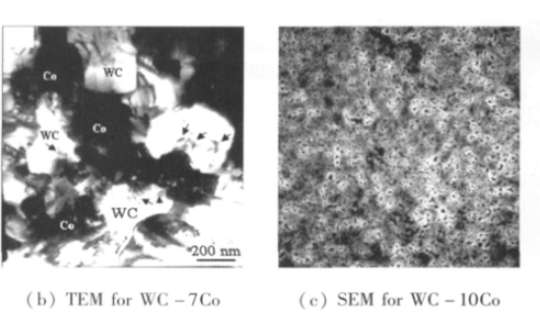

Abstract : The two key factors for the preparation of nano / ultrafine WC – Co cemented carbides are the prep -Aration of high – quality nano/ ultrafine WC – Co composite powders and the control of grain growth during…