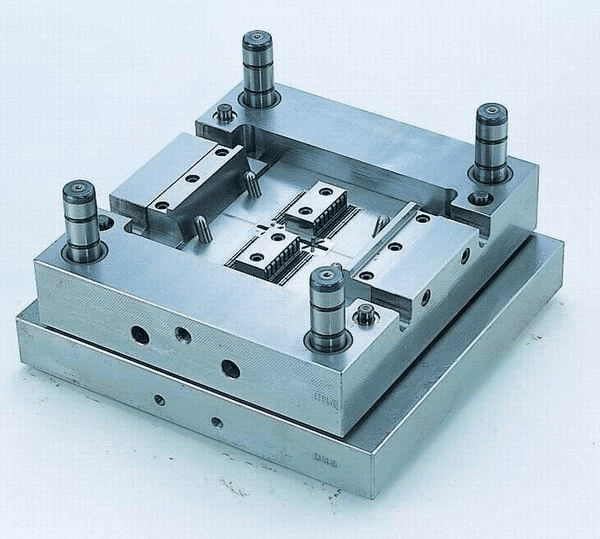

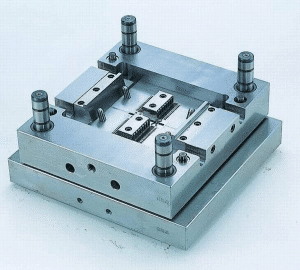

Nowadays, the machining of a set of mold comprises the following steps:

Roughing, heat treatment, fine finishing,electro-machining, bench work, and assemble.

Roughing and fine finishing is the two steps for milling cutters to participate.

Roughing die is to pursue the metal removal rate per unit time and to prepare the geometric profile of the workpiece for semi-finishing. Semi-finishing of mold is to further homogenize the machining allowance. In the two parts, indexable insert milling cutter, which can work at very high cutting feed. High metal removal rates are achieved by cutters for high speed cutting. That’s because the cutting force of it is mainly produced in the axial direction.

The final quality of the part is guaranteed by finishing. In most mold manufacturing companies, the methods used in the finishing stage are generally grinding, electric machining and fitter processing.

Critical factors that matter in machining of mold

- Accuracy of machining. Generally, a whole set of mold are made of cavity mold, male mold, and mold carrier, or many pieces molduld blocks. Only high dimension precision of the parts enables smooth their assembly. Precision moulds commonly tend to have dimension accuracy of μm

- Intricate shape. Some molds of airplane components, toys, and household appliance are with many curved surfaces, which make cavity of mould difficult to processing.

- Small production scale. In many cases there is no need to mass-produce mould.

- Multiple processes such as milling, boring, drilling, reaming and tapping should beused in the mold processing.

- Sometimes there are no drawings and no data in the production of molds, and it is necessary to carry out profiling according to the actual objects. This requires high precision and no distortion.

- The main materials of the mold are mostly made of high-quality alloy steel, especially the mold with long service life, which is often made of Crl2, CrWMn, and other Leysite steel. Heat deformation of these materials is also an issue that needs to be taken seriously in processing.

The strategy to choose the cutters for profile milling

Based on the shape of the working part, they can be divided into three types: a conical flat head, a cylindrical ball head, and a conical ball head. According to the material, They are divided into carbide milling cutter and HSS mold milling cutter. Carbide cutters are used in a wide range of applications. In addition to milling various mold cavities, they can also be used to machine workpieces formed by casting, forging and welding.

In roughing & semifinishing

Roughing larger planar or beveled profiles should involve those indexable insert end mills, face milling cutters, and large cutting feed milling cutters should be used.

Roughing and semi-finishing of big profiles should be used with round insert end mills, which has a large arc radius and a large blade strength. It is most suitable for contour, cavity and contour processing.

As to roughing and semi-finishing of smaller profiles, ball-end milling cutters with indexable inserts are widely used, which get blade shape in willow shape that supports small cutting force and high processing efficiency. Besides, Index-able willow ball head milling cutter is more suitable for stamping die processing.

In fine finishing

The finishing of the larger profile can be achieved by using the indexable insert ball-end ball finishing end mills. the finishing of the smaller profile can be achieved with the integral ball end mill for high-precision machining. For deep groove and corner parts of small size and width, a small-diameter solid carbide tool can be used for its root cleaning and clear angle processing of each workpiece.