Reasonable selection of tool geometry makes it possible to improve machining conditions, save machining time, improve machining efficiency, ensure the quality of the workpiece being machined, and extend the service life of the tool. Select the angle of the tool from the type of tool.

1.Method / step

Traditional welding tool

When roughing, it is important to ensure the longest tool life. When finishing, the main consideration is to ensure the machining accuracy and the quality of the machined surface. When the rigidity and power of the machine are insufficient, the tool stress is sharp (such as increasing the rake angle and the main Deflection, reduce the blunt radius of the cutting edge, etc.) to reduce cutting forces and vibration.

In the welding turning tool:

(1) the greater value is selected for the finishing of the front corner, and the smaller value is selected for the roughing; when the plasticity and toughness of the processed material are high, the rake angle is larger; when the strength and hardness are high, the rake angle is smaller; The brittleness and hardened material have small or negative rake angles; increasing the rake angle can reduce cutting deformation and friction. Therefore, it has less influence on the formation of built-up edge, scales, work hardening, etc., but the surface roughness is processed. low.

(2) The finishing angle of the back corner is larger, the roughing is smaller; the back angle is larger when cutting the plastic metal; the back angle of the brittle metal is smaller, the cutting strength and hardness are higher, the back angle of the material is smaller, and the material with high cutting toughness is easy to stick. The scraper angle is selected to be larger; for example, the high-speed steel cutter has higher bending strength and toughness, so the rake angle is larger; the cemented carbide tool has a smaller rake angle.

(3) When the rigidity of the machining system is allowed, reducing the main declination can reduce the surface roughness height and improve the surface quality;

(4) When the absolute value of the rake angle increases, the actual working angle increases, so the cutting deformation is small.

2 machine clip cutter

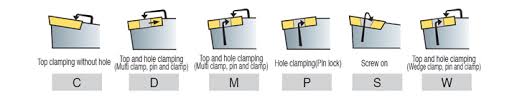

The machine clamp tool is an ordinary blade. The blade is fixed on the tool bar by mechanical reinforcement. Compared with the traditional welding tool, the machine clamp tool avoids welding internal stress and causes the tool life to decrease, and the tool bar utilization rate is high. The blade can be sharpened to obtain the use parameters, which is flexible and convenient to use. After the blade is worn, the blade is directly removed and replaced with a new one, which saves time and improves processing efficiency.

3 indexable turning tools

With the popularity of CNC lathes, the application range of indexable turning tools is increasingly wide. The indexable turning tool can be quickly indexed and dimensionally stable during processing, and can be quickly replaced after the blade is worn.

In the indexable turning tool

(1) the size of the front angle directly affects the strength and sharpness of the blade. Increasing the rake angle reduces chip deformation, making the cutting lighter and advances tool life. However, if the rake angle is too large, the cutting edge strength will be weakened, and it will be easy to chip, which will shrink the tool life.

(2) The rear corner is used to reduce the conflict between the flank and the transition profile during the cutting process. When designing the indexable turning tool, it is necessary to consider the back angle and the front angle as the analysis. After selecting the back corner of the blade, the back angle of the insert groove must be determined according to the front corner of the insert.

(3) The main declination kr main declination has a great influence on the life of the indexable turning tool. In general, reducing the lead angle can extend the tool life. However, when the workpiece is not rigid enough, reducing the lead angle will increase the radial force, causing machining vibration and affecting the tool life.

(4) When the workpiece is finished, to prevent the chip from flowing and scratching the processed profile, the blade The dip angle is often taken as a positive value. In addition, the size of the blade inclination also affects the sharpness of the cutting edge.

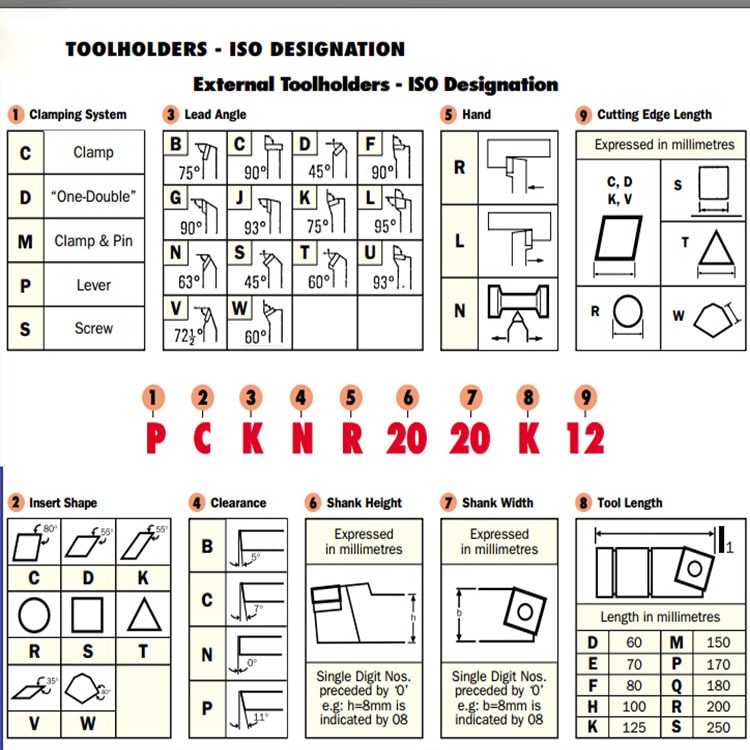

The standard machine clamp can be used to index the lead angle of the outer turning tool and the inner hole turning tool. The front angle, the back angle and the blade inclination angle are generally designed standard structures, and the type of the tool holder is the national standard model code. The machining technician can select the turning tool model according to the shape and size of the machined workpiece and the path to the tool. The tool bar representation method of the standard indexable external turning tool (as shown below):

4.Features of three turning tools:

(1) Welding turning tool: The structure is simple and compact; the seismic performance is good, the manufacturing is convenient, and the use is flexible; but the blade is easy to be broken, the blade and the tool bar material are not fully utilized; there is welding stress.

(2) Machine-type turning tool: no high-temperature welding; long service time (good wear resistance), high productivity; repeated use of the tool bar, many times of blade re-grinding; platen chip breaking; need to be re-grinded );

(3) Indexable turning tool: no need for welding, re-grinding, good blade performance; high productivity; easy to replace, easy to guarantee processing accuracy.

5 summary:

In summary, with the development of modern technology, the turning tools have also changed from the traditional welding turning tools to the machine-clamp turning tools, and the indexable turning tools for standard CNC blades that are commonly used nowadays; The popularity of high-speed cutting machine tools has improved production efficiency, ensured the precision of cutting, and extended the service life of the blades.